A Fly Ash Bricks Making Machine is a specialized industrial machine used to manufacture bricks using fly ash—a byproduct from coal combustion in thermal power plants—along with materials like sand, cement, lime, and gypsum. These bricks are an eco-friendly alternative to traditional clay bricks.

---

🔧 Types of Fly Ash Bricks Making Machines

1. Manual Machines

Requires manual input for most functions.

Low cost, low output.

Suitable for small-scale operations.

2. Semi-Automatic Machines

Some processes are automated (e.g., mixing, pressing).

Moderate production capacity.

Ideal for medium-scale brick production.

3. Fully Automatic Machines

Fully automated operation including material feeding, mixing, brick forming, and stacking.

High production capacity.

Ideal for large-scale industrial use.

---

🧱 Typical Raw Materials Used

Fly ash (60–70%)

Sand or stone dust (20–30%)

Cement or lime (8–12%)

Gypsum (2–3%)

Water

---

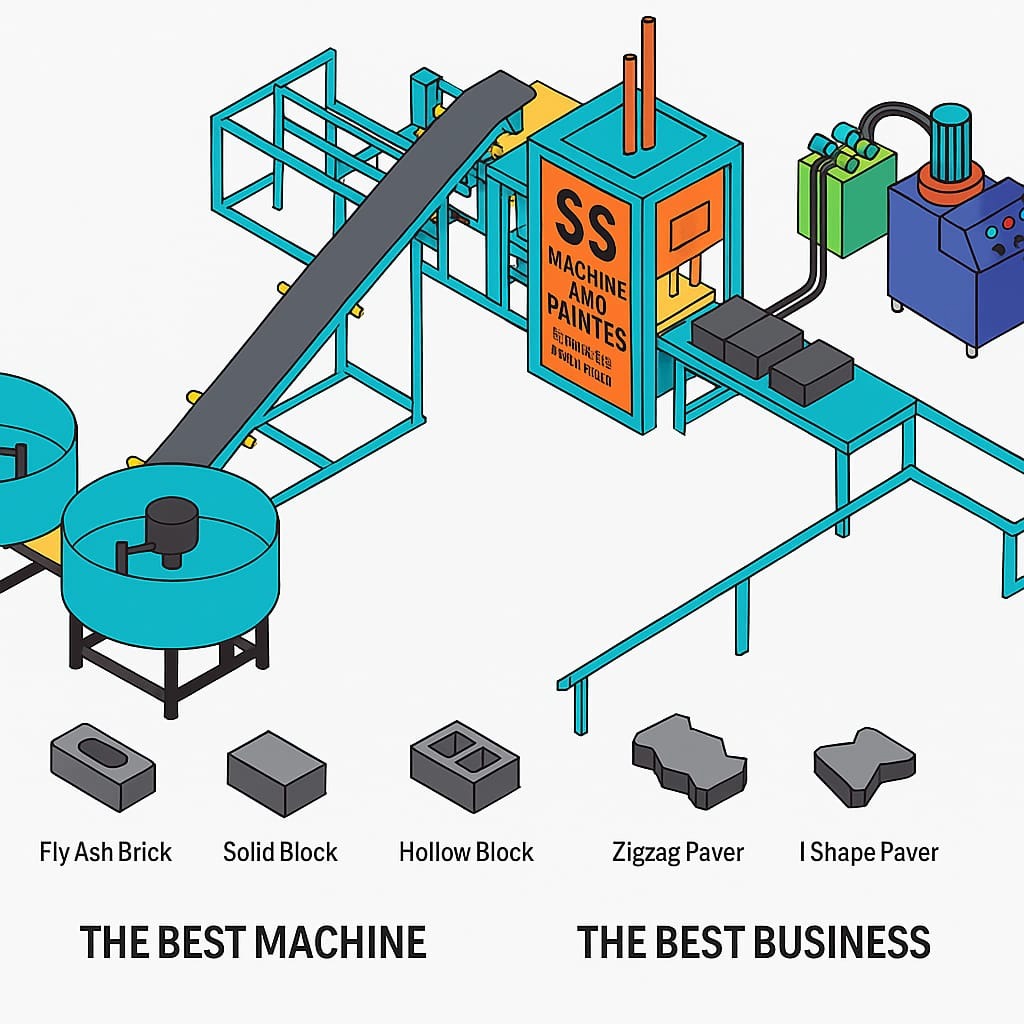

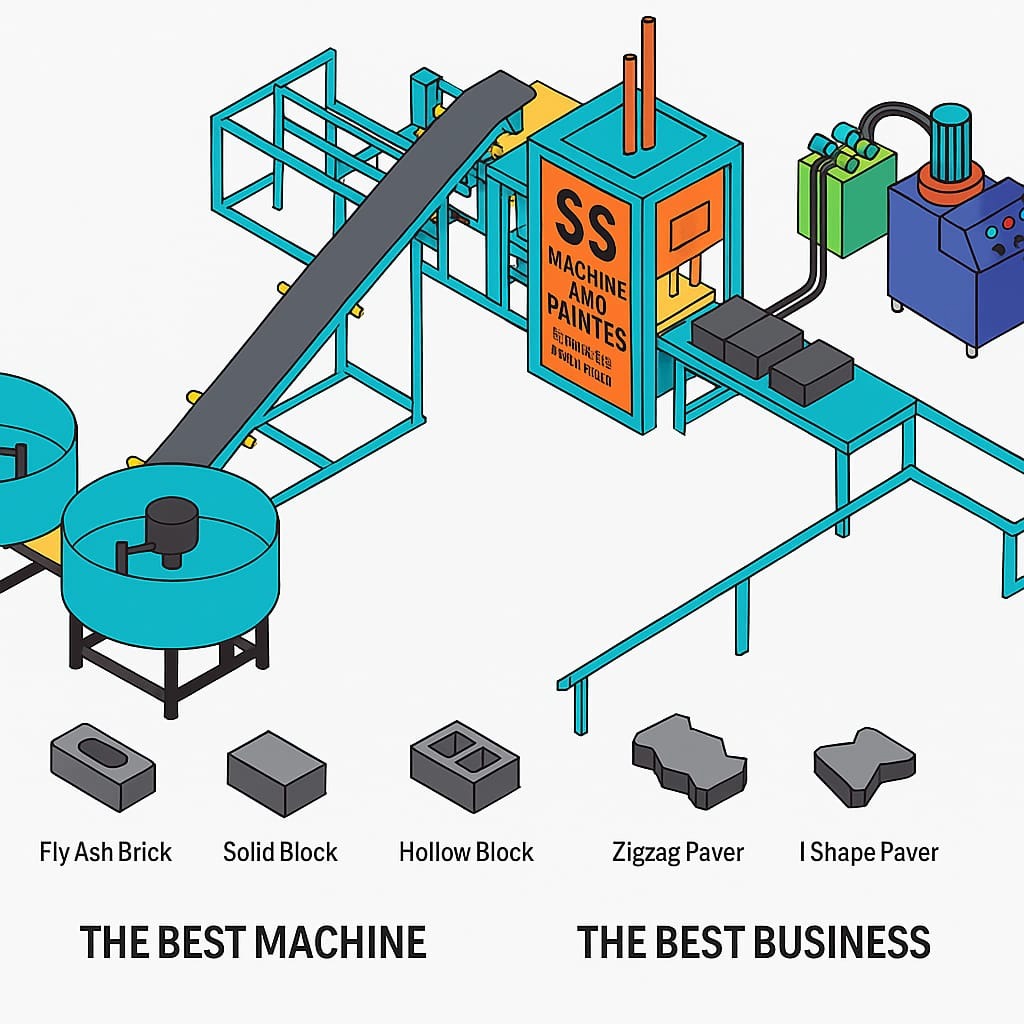

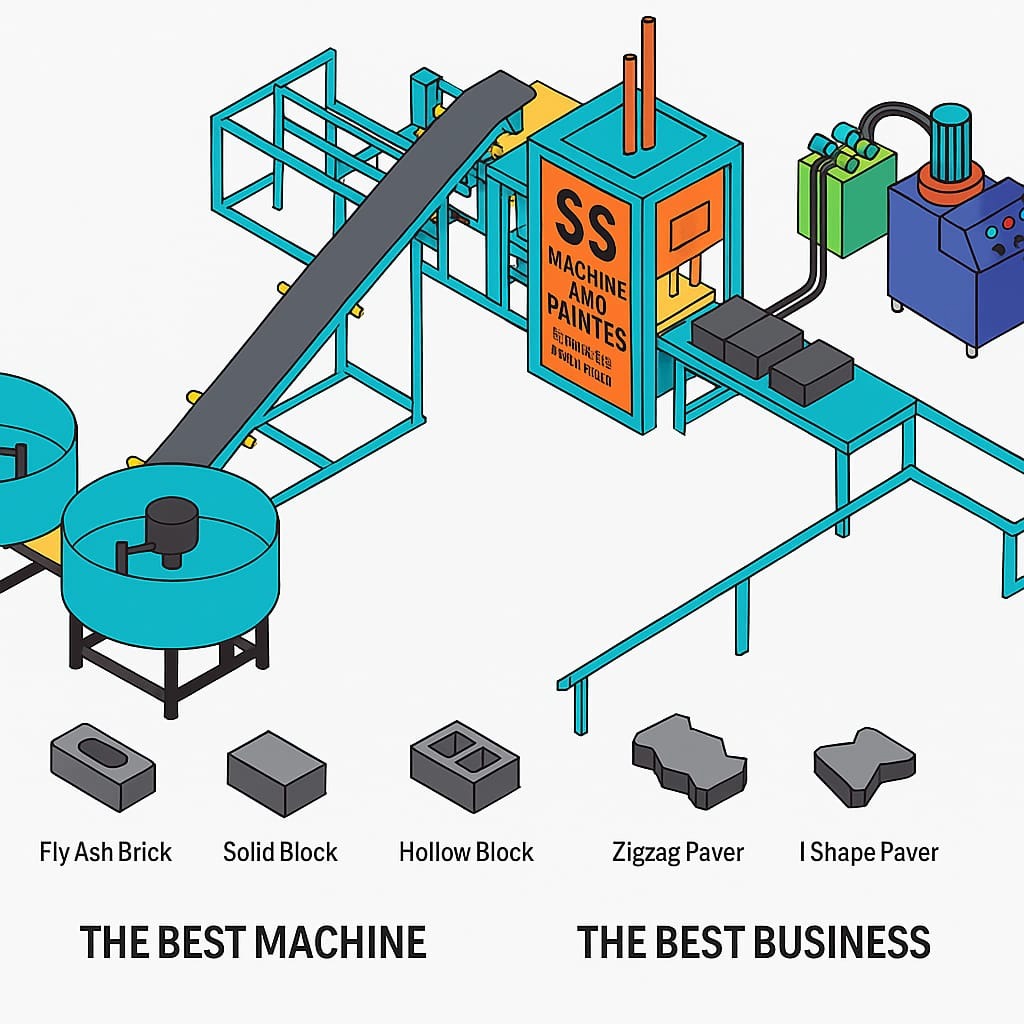

⚙️ Key Components

Pan Mixer or Concrete Mixer

Conveyor Belt

Brick Press Machine (Hydraulic or Mechanical)

PLC Control System (in automatic models)

Pallet Stacker / Brick Stacker

Curing Chamber (optional)

---

📈 Production Capacity (Example)

Machine Type Bricks per Hour Power Required

Manual 300–500 5–10 HP

Semi-Automatic 1, 000–2, 500 15–25 HP

Fully Automatic 4, 000–10, 000+ 25–50 HP

---

✅ Advantages of Fly Ash Bricks

Environmentally friendly (utilizes industrial waste)

High compressive strength

Better water resistance

Uniform shape and size

Lower cost in the long run

---

🛠️ Popular Manufacturers (India & Global)

Mak machine engineering works indore I'm manufactur mo. 9993695533